Automatic Frozen Potato Chips Production Line(capacity of 1.5t/H)

Application:This automatic frozen potato chips production line is mainly used to produce frozen potato chips.

Raw Material:Potato,edible oil,salt

Capacity:1.5t/h

Loading Porting:Shanghai Port/Qingdao Port

Voltage:50Hz/380v

Features:

This automatic frozen potato chips line is automatic from feeding material to finished potato chips.

Introduction:

1, Pre-washing Machine: By Elevator, the potato will come into the Pre-washing Machine, by brush roller and water spraying to remove the mud on the surface of potato. The electrical is Schneider, and frequency control motor. The Frequency converter from Japanese Mitsubishi.

After pre-washing, the potato will come into the emery peeling machine to remove the peel.

2,Emery Peeling Machine: After processed by Emery roll and water spraying , the peel will be removed.Total 12 pcs of emery roller.At the bottom , it is with one water tank to recycle use the water, thus, it can saving water.The potato will be discharged automatically by screw. Peeling Time is adjustable, frame all with 50*50*2mm, superior Stainless Steel 304 tube, bearing is made of Stainless Steel 316 Bearings. All motors are with superior copper wire and adjustable-speed, working speed is adjustable.

3, All machines are made of Stainless Steel 304.

This automatic frozen potato chips line is automatic from feeding material to finished potato chips.

Introduction:

1, Pre-washing Machine: By Elevator, the potato will come into the Pre-washing Machine, by brush roller and water spraying to remove the mud on the surface of potato. The electrical is Schneider, and frequency control motor. The Frequency converter from Japanese Mitsubishi.

After pre-washing, the potato will come into the emery peeling machine to remove the peel.

2,Emery Peeling Machine: After processed by Emery roll and water spraying , the peel will be removed.Total 12 pcs of emery roller.At the bottom , it is with one water tank to recycle use the water, thus, it can saving water.The potato will be discharged automatically by screw. Peeling Time is adjustable, frame all with 50*50*2mm, superior Stainless Steel 304 tube, bearing is made of Stainless Steel 316 Bearings. All motors are with superior copper wire and adjustable-speed, working speed is adjustable.

3, All machines are made of Stainless Steel 304.

| Item | Parameter |

| 1.Pre-washing Elevator |

Power: 750W, Dimension:1800*1200*1500mm |

| 2. Pre-Washing Machine | Power:5.1KW, Dimension:3000*900*1400mm |

| 3.Elevator |

Power:750W, 380V/50HZ Dimension: 2000*1000*1600mm |

| 4.Emery Peeling Machine | After pre-washing, the potato will come into the emery peeling machine to remove the peel. After processed by Emery roll and water spraying , the peel will be removed.Total 12 pcs of emery roller.At the bottom , it is with one water tank to recycle use the water, thus, it can saving water.The potato will be discharged automatically by screw. Peeling Time is adjustable, frame all with 50*50*2mm, superior Stainless Steel 304 tube, bearing is made of Stainless Steel 316 Bearings. All motors are with superior copper wire and adjustable-speed, working speed is adjustable, frequency converter is from Jananese Mitsubishi, electrical is from Schneider. |

|

5.Sorting Conveyor |

After potato peeled, the potato will come into the sorting conveyor. Then can sort the unqualified potato,potato is not peeled well.If the the potato is not peeled well,then process it. The conveyor is made of PVC Superior Food Standard Conveyor, healthy and safe,meet food requirement. All plate made of Stainless Steel 304, the motor are speed adjustable,conveyor working is adjustable.Dimension of 5000*1000*950mm, bearing seat are FL206 Stainless Steel bearing seat.Seat made of Stainless Steel 304,height is adjustable. Power;0.75KW,380V, 50HZ |

| 6.Waste Transfer Cart | On both sides of the sorting conveyor, it will be put two pcs of cart. Thus the waster can be put inside. After finished working, to discharge them together. All made of Stainless Steel 304. Dimension: 600*500*400 |

| 7. Potato Chips Cutting Machine(Two Sets) |

After sorted well, qualified potatoes will be put into the cutting machine. It can cut continuous. Dimension: 900*850*900mm Capacity:1500kg/h Power:1.1kw Weight:120kg |

| 8.Elevator |

The elevator with mesh of stainless steel 304, mesh size of 3mm, all frame of 50*50*2mm, superior stainless steel 304 tubes, bearings are made of stainless steel 316 bearings, All motors are with superior copper wire and adjustable-speed, working speed is adjustable, frequency converter is from Jananese Mitsubishi, electrical is from Schneider. Dimension:1500*1000*1500mm Power:750W/380V,50HZ |

| 9.Impurity Removing Machine |

After the potato chips finished cutting, elevator will send potato chips to the Impurity Removing Machine. To adjust the distance between rollers, general it is 4mm soft brush roller. Potato chips will go down under working of brush roller. If the size of potato chips is less than 4mm, it will leave out. There is one material receiving tank. Thus it can get the effect of sorting. Brush roller material is food standard nylon yarn. Dimension:2600*1000*1400mm Power:1.5KW, Weight:380KG |

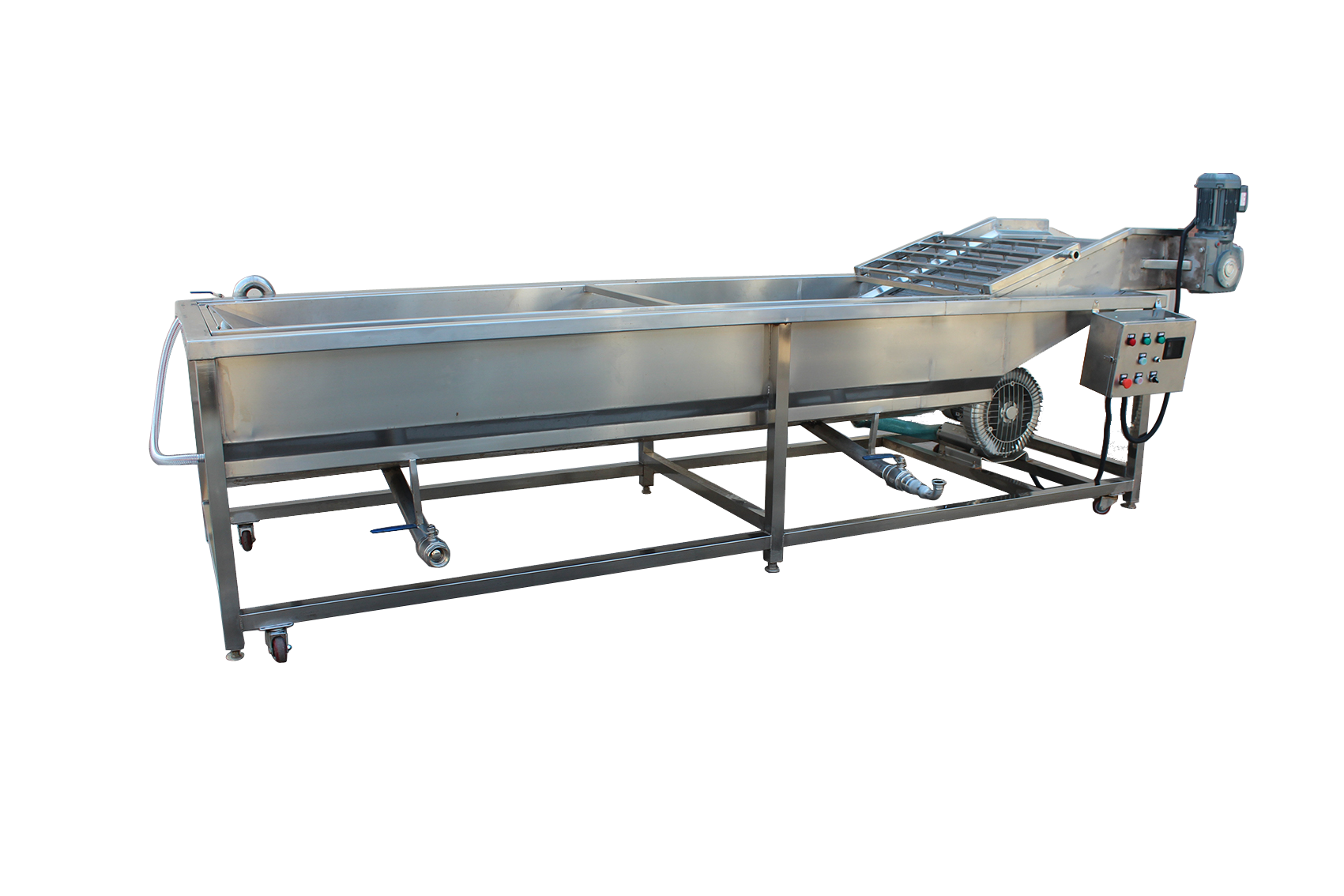

| 10.Rinsing Machine |

After the potato chips coming from the Impurity Removing Machine, the qualified potato chips will drop the Rinsing machine directly. By bubble Agitator Wave Wash, the potato chips will be in roll state, thus it can remove the starch on the surface of potato chips.It also with second water spraying function. All bubble produce device are with speed adjustable.All mesh are with size of 5mm.Width of belt is 800mm. Dimension:6000*1600*1400mm Power:3.7KW,380V,50HZ |

| 11. Blanching Machine | After rinsed , potato chips will coming into blanching machine, this blanching machine is adopts with electricity heating. Water temperature is controlled, all material are made of stainless steel 304, all bearings are Stainless steel 304, and stainless steel 304 bearing seat.Width of 800mm,mesh with size of 3mm. This machine will prevent the activities of enzyme, thus it can |

| 12. Vibrating De-watering Machine |

After blanched, potato chips will be sent to Viberating De-watering Machine, with frequency viberate to remove the water on the surface.This machine is made of Stainless Steel 304,thickness of 3mm. Superior stainless steel 304 tube,viberate motor of 0.25kw,amplitude is adjustable. Working Principle:under high frequency vibrating, the water on the surface on potato chips, then the potato chips will come into the air de-water machine under vibrating. Dimension:1800*1500*1300mm |

|

13.Air De-watering Machine |

After Vibrating dewatering machine, the potato chips will coming into the air de-watering machine, thus the water will remove completely. This air dewater line is made of Stainless Steel 304, frequency control motor speed,mesh type to be six turn one flat, width of belt is 1200mm. total 16 pcs of fan, power of each fan is 750W. The air intake vent is with high-density filter system.The bearing are made of superior stainless steel, height of fan is adjustable, Its working principle is to send the potato chips by conveyor, after turn over many time to realize the potato chips will be wind uniform and polyhedral winded.By high press of wind of the fan,the water on the surface will be removed.the fan nozzle is with blade shape,it will improve the pressure of wind, and the water will be easier to be removed. In order to follow up process,there is one water received tank at the bottom of this amchien. Dimension:8000*1600*1600mm Power:15KW,380V,50HZ,Three-phase. |

| 14. Stainless Steel Elevator |

The motor is speed adjustable,made of Stainless Steel 304, all bearings are Stainless Steel Bearing. Power:750W,380V,50HZ Dimension:2000*1500*1350mm |

| 15.Fryer Machine |

This machine is made of pure oil process technology, it is with dynamic filting system, it can filt and discharge the residue automatically to make sure the qulity of the oil. All made of Stainless Steel 304, Power of 2.2kw frequency control speed motor, three parts to control temperature, mesh conveyor width of 1200m ,with elevator function automatically. It will be easier to clean. It is with double layer mesh conveyor, upper and down conveyor all frequency control, oil temperature is adjustable from normal temperature to 300 centigrade. The electrical is from Schneider or Omron.There is not oil adding port. Working Principle: after the potato chips send into the fryer machine, the oil temperature is 185centigrade, the second section will be set to be 160 centigrade. The third section temperature to be 120 centigrade. The potato chips will be fried for 1-2 minutes in oil. Then will be discharged out. This frye rmachine is with Elecric Heating. Dimension:8000*1600*2400mm |

| 16.Oil Filting Machine | When equipment working, the oil will from fryer into filter under pressure difference between the both sides. Then the oil will be send to fine filter by pump. Under the fine filter paper working, it will remove the supermicro granule. Then the oil coming from the filter discharge hole is qualified . then with pipes, the oil will be sent to fryer machine to finish static filting and finish the whole filting process. |

| 17.Oil Adding Tank | Oil Adding Tank is with heating device. It will heat the oil to the certain temperature. Then by recycle pump to send the oil to the fryer to realize the adding oil . |

| 18. Vibrating Oil-Removing Machine |

This machine is made of Stainless Steel 304, thickness of 3mm, frame made of 100*50*5mm, superior stainless steel 304, vibrating motor of 0.25kw, amplitude is adjustable. Working Principle:Under the high frequency of motor, it will remove the oil on the surface of potato chips, then the potato chips will coming into the air de-oil machine. |

| 19.Air De-oil Line |

This machine is made of SS304, Speed adjustable motor, be six turn one flat, width of belt is 800mm. total 16 pcs of fan, power of each fan is 750W. The air intake vent is with high-density filter system.The bearing are made of superior stainless steel, height of fan is adjustable, Its working principle is to send the potato chips by conveyor, after turn over many time to realize the potato chips will be wind uniform and polyhedral winded.By high press of wind of the fan,the oil on the surface will be removed.the fan nozzle is with blade shape,it will improve the pressure of wind, and the oil will be easier to be removed. Dimension: 8000x1600x1600mm Power:15kw/ 380V/50Hz 3 phase |

| 20. Elevator |

This machine is made of Stainless Steel food standard conveyor, safe and healthy, meet food requirement. Frame of 50*50*2mm, superior SS304 tubes with thickness of 2mm. Bearings made of SS316 bearings. All motor are speed adjustable. Power: 0.75KW/380V/50HZ Dimension:2000*100081600mm |

| 21. Distributing Machine |

Made of Stainless Steel 304, thickness of 3mm, frame tubes are with 100*50*5mm, superior SS304, vibrating motor of 0.25kw, amplitude is adjustable. Working principle: under the high frequency vibrating, the potato chips will be distribute on the frozen belt to avoid potato chips stick together. |

| 22. Frozen Tunnel |

Power: 300kw/380v/50hz Dimension: 20000*3000*3000mm |

| 23.Automaic Packing Machine | 3000*2000*2600mm |

Product Catalog

Contact Us

Email:serena@machinehall.com

Skype:serenayan666

Whatsapp:0086-15515597212

Tel:0086-15515597212

ADD:Building 8, Jingkai Square, No.1507, Hanghai East Road, Free Trade Zone, Zhengzhou, China.