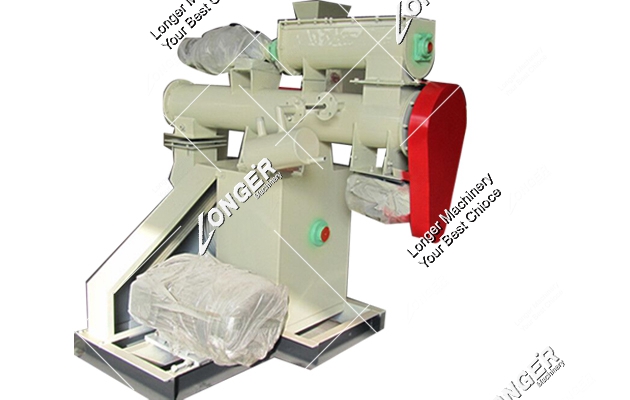

LG-300 Animal Feed Pellet Machine In High Capacity

Application:This feed pellet machine raw material is not only used for hard sawdust,wood,tree branch,corn cob,wheat straw,corn stalk etc,but soft material,such as rice husk,palm fiber,coconut shell,peanut shell,wood sawdust etc.

Raw Material:wood,tree branch

Capacity:1.5-2.5T/H

Loading Porting:Shanghai Port/Qingdao Port

Voltage:50HZ/220-380V

Features:

The feed pellet machine is especially for making wood pellet and feed pellet.It is multifunctional equipment.

1. Main engine drives with high precision gear, ring die in quick detaching encircling hoop type ,output higher 20% than belt drive.

2. The complete machine transmission parts include electric motor with high quality bearing, ensure high efficiency ,stable and low noise drive.

3. Large type strengthen feeding conditioner in entire stainless steel with frequent speed control.ensure the high quality of pellet .

4. Adopt international advanced righ die processed by heat treatment vacuum furnace, lengthen useful lifte and pellet is smooth with high quality.

5. With full stainless steel door, flume and pull cutter which is convenient ,reliable,

6. Customized pellet machine with double layers or three layers.

7. Pellet machine can work continuously for 24 hours, no need to stop.

8. Using frequency conversion,to avoid the nonuniform feeding due to unstable voltage.

9.Added humidity control function,make sure the humidity of feedstock is uniform and improve the quality.

10.The ring die uses quick-release type without beam clamp,high-quality stainless steel are also adopted,and disassembly easy.

11. All of the interior accessories use excellent forging parts to make sure the machine run stably and reduce the failure rate.

The feed pellet machine is especially for making wood pellet and feed pellet.It is multifunctional equipment.

1. Main engine drives with high precision gear, ring die in quick detaching encircling hoop type ,output higher 20% than belt drive.

2. The complete machine transmission parts include electric motor with high quality bearing, ensure high efficiency ,stable and low noise drive.

3. Large type strengthen feeding conditioner in entire stainless steel with frequent speed control.ensure the high quality of pellet .

4. Adopt international advanced righ die processed by heat treatment vacuum furnace, lengthen useful lifte and pellet is smooth with high quality.

5. With full stainless steel door, flume and pull cutter which is convenient ,reliable,

6. Customized pellet machine with double layers or three layers.

7. Pellet machine can work continuously for 24 hours, no need to stop.

8. Using frequency conversion,to avoid the nonuniform feeding due to unstable voltage.

9.Added humidity control function,make sure the humidity of feedstock is uniform and improve the quality.

10.The ring die uses quick-release type without beam clamp,high-quality stainless steel are also adopted,and disassembly easy.

11. All of the interior accessories use excellent forging parts to make sure the machine run stably and reduce the failure rate.